MAX78002EVKIT

Overview

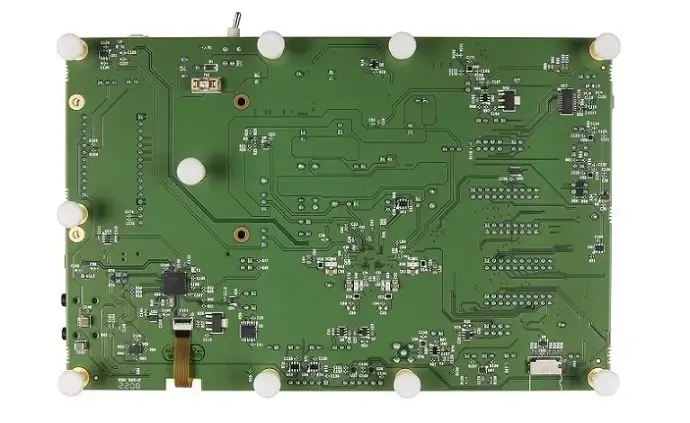

The MAX78002 evaluation kit (EV kit) provides a platform and tools for leveraging device capabilities to build new generations of artificial intelligence (AI) products.

The kit provides optimal versatility with a modular peripheral architecture, allowing a variety of input and output devices to be remotely located. DVP and CSI cameras, I2S audio peripherals, digital microphones, and analog sensors are supported, while a pair of industry-standard QWIIC connectors supports a large and growing array of aftermarket development boards. An onboard stereo audio codec offers line-level audio input and output, and tactile input is provided by a touch-enabled 2.4in TFT display. The MAX78002 energy consumption is tracked by a power accumulator, with four channels of formatted results presented on a secondary TFT display. All device GPIOs are accessible on 0.1in pin headers. A standard coaxial power jack serves as power input, using the included 5V, 3A wall-mount adapter. Two USB connectors provide serial access to the MAX78002, one directly and the other through a USB to UART bridge. A third USB connector allows access to the MAX78002 energy consumption data. Rounding out the features, a microSD connector provides the capability for inexpensive highdensity portable data storage.

The Zephyr port is running on the MAX78002 MCU.

Hardware

MAX78002 MCU:

Dual-Core, Low-Power Microcontroller

Arm Cortex-M4 Processor with FPU up to 120MHz

2.5MB Flash, 64KB ROM, and 384KB SRAM

Optimized Performance with 16KB Instruction Cache

Optional Error Correction Code (ECC SEC-DED) for SRAM

32-Bit RISC-V Coprocessor up to 60MHz

Up to 60 General-Purpose I/O Pins

MIPI Camera Serial Interface 2 (MIPI CSI-2) Controller V2.1

Support for Two Data Lanes

12-Bit Parallel Camera Interface

I2S Controller/Target for Digital Audio Interface

Secure Digital Interface Supports SD 3.0/SDIO 3.0/eMMC 4.51

Convolutional Neural Network (CNN) Accelerator

Highly Optimized for Deep CNNs

2 Million 8-Bit Weight Capacity with 1-, 2-, 4-, and 8-bit Weights

1.3MB CNN Data Memory

Programmable Input Image Size up to 2048 x 2048 Pixels

Programmable Network Depth up to 128 Layers

Programmable per Layer Network Channel Widths up to 1024 Channels

1- and 2-Dimensional Convolution Processing

Capable of Processing VGA Images at 30fps

Power Management for Extending Battery Life

Integrated Single-Inductor Multiple-Output (SIMO) Switch-Mode Power Supply (SMPS)

2.85V to 3.6V Supply Voltage Range

Support of Optional External Auxiliary CNN Power Supply

Dynamic Voltage Scaling Minimizes Active Core Power Consumption

23.9μA/MHz While Loop Execution at 3.3V from Cache (CM4 only)

Selectable SRAM Retention in Low-Power Modes with Real-Time Clock (RTC) Enabled

Security and Integrity

Available Secure Boot

AES 128/192/256 Hardware Acceleration Engine

True Random Number Generator (TRNG) Seed Generator

External devices connected to the MAX78002 EVKIT:

Color TFT Display

Audio Stereo Codec Interface

Digital Microphone

A 8Mb QSPI ram

Supported Features

The max78002evkit board supports the hardware features listed below.

- on-chip / on-board

- Feature integrated in the SoC / present on the board.

- 2 / 2

-

Number of instances that are enabled / disabled.

Click on the label to see the first instance of this feature in the board/SoC DTS files. -

vnd,foo -

Compatible string for the Devicetree binding matching the feature.

Click on the link to view the binding documentation.

max78002evkit/max78002/m4 target

Type |

Location |

Description |

Compatible |

|---|---|---|---|

CPU |

on-chip |

ARM Cortex-M4F CPU1 |

|

ADC |

on-chip |

ADI MAX32 ADC SAR1 |

|

Clock control |

on-chip |

MAX32 Global Control1 |

|

on-chip |

|||

Counter |

on-chip |

ADI MAX32 counter6 |

|

on-chip |

ADI MAX32 compatible Counter RTC1 |

||

on-chip |

ADI MAX32 Wake-Up Timer is a unique instance of a 32-bit timer that can wake up the device from sleep, standby and backup modes1 |

||

DMA |

on-chip |

ADI MAX32 DMA1 |

|

Flash controller |

on-chip |

MAX32XXX flash controller1 |

|

GPIO & Headers |

on-chip |

MAX32 GPIO4 |

|

I2C |

on-chip |

||

Input |

on-board |

Group of GPIO-bound input keys1 |

|

Interrupt controller |

on-chip |

ARMv7-M NVIC (Nested Vectored Interrupt Controller)1 |

|

LED |

on-board |

Group of GPIO-controlled LEDs1 |

|

MTD |

on-chip |

Flash node1 |

|

Pin control |

on-chip |

MAX32 Pin Controller1 |

|

PWM |

on-chip |

ADI MAX32 PWM6 |

|

RNG |

on-chip |

ADI MAX32XXX TRNG1 |

|

Serial controller |

on-chip |

||

SPI |

on-chip |

||

SRAM |

on-chip |

Generic on-chip SRAM8 |

|

Timer |

on-chip |

ARMv7-M System Tick1 |

|

on-chip |

ADI MAX32 timer7 |

||

1-Wire |

on-chip |

ADI MAX32xxx MCUs 1-Wire Master1 |

|

Watchdog |

on-chip |

Connections and IOs

Name |

Name |

Settings |

Description |

||||

|---|---|---|---|---|---|---|---|

JP1 |

3V3 MON |

|

|

||||

JP2 |

3V3 SW PM BYPASS |

|

|

||||

JP3 |

CNN MON |

|

|

||||

JP4 |

VCOREA PM BYPASS |

|

|

||||

JP5 |

VCOREB PM BYPASS |

|

|

||||

JP6 |

VREGO_A PM BYPASS |

|

|

||||

JP7 |

VBAT |

|

|

||||

JP8 |

VREGI |

|

|

||||

JP9 |

VREGI/VBAT |

|

|

||||

JP10 |

VDDIOH |

|

|

||||

JP11 |

VDDA |

|

|

||||

JP12 |

VDDIO |

|

|

||||

JP13 |

VCOREB |

|

|

||||

JP14 |

VCOREA |

|

|

||||

JP15 |

VREF |

|

|

||||

JP16 |

I2C1 SDA |

|

|

||||

JP17 |

I2C1 SCL |

|

|

||||

JP18 |

TRIG1 |

|

|

||||

JP19 |

TRIG2 |

|

|

||||

JP20 |

UART0 EN |

|

|

||||

JP21 |

I2C0_SDA |

|

|

||||

JP22 |

I2C0_SCL |

|

|

||||

JP23 |

UART1 EN |

|

|

||||

JP24 |

EXT I2C0 EN |

|

|

||||

JP25 |

PB1 PU |

|

|

||||

JP26 |

PB2 PU |

|

|

||||

JP27 |

I2C2 SDA |

|

|

||||

JP28 |

I2C2 SCL |

|

|

||||

JP29 |

VDDB |

|

|

||||

JP30 |

EXT I2C2 EN |

|

|

||||

JP31 |

L/R SEL |

|

|

||||

JP32 |

MIC-I2S I/O |

|

|

||||

JP33 |

MIC-I2S/CODEC |

|

|

||||

JP34 |

I2S VDD |

|

|

||||

JP35 |

I2C1 SDA |

|

|

||||

JP36 |

I2C1 SCL |

|

|

||||

JP37 |

I2S CK SEL |

|

|

||||

JP38 |

DVP CAM PWR |

|

|

||||

JP39 |

SW CAM PWUP |

|

|

||||

JP40 |

HW PWUP / SW PWUP |

|

|

||||

JP41 |

CSI CAM I2C EN |

|

|

||||

JP42 |

TFT DC |

|

|

||||

JP43 |

TFT CS |

|

|

||||

JP44 |

LED1 EN |

|

|

||||

JP45 |

LED2 EN |

|

|

Programming and Debugging

The max78002evkit board supports the runners and associated west commands listed below.

| flash | debug | attach | rtt | debugserver | reset | |

|---|---|---|---|---|---|---|

| jlink | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

| openocd | ✅ (default) | ✅ (default) | ✅ | ✅ | ✅ |

Flashing

The MAX78002 MCU can be flashed by connecting an external debug probe to the SWD port. SWD debug can be accessed through the Cortex 10-pin connector, JH8. Logic levels are fixed to VDDIO (1.8V).

Once the debug probe is connected to your host computer, then you can simply run the

west flash command to write a firmware image into flash. To perform a full erase,

pass the --erase option when executing west flash.

Note

This board uses OpenOCD as the default debug interface. You can also use

a Segger J-Link with Segger’s native tooling by overriding the runner,

appending --runner jlink to your west command(s). The J-Link should

be connected to the standard 2*5 pin debug connector (JH8) using an

appropriate adapter board and cable.

Debugging

Please refer to the Flashing section and run the west debug command

instead of west flash.